Our product line contains full-ceramic drum mills as well as grinding vessels. We were able to significantly enlarge our product range by incurring product line of the Cera System Verschleißschutz GmbH in December 2016. We produce the drum mills in different sizes up to a volume of 300 liters, various grinding vessels and the fitting grinding balls.

Our product line contains full-ceramic drum mills as well as grinding vessels. We were able to significantly enlarge our product range by incurring product line of the Cera System Verschleißschutz GmbH in December 2016. We produce the drum mills in different sizes up to a volume of 300 liters, various grinding vessels and the fitting grinding balls.

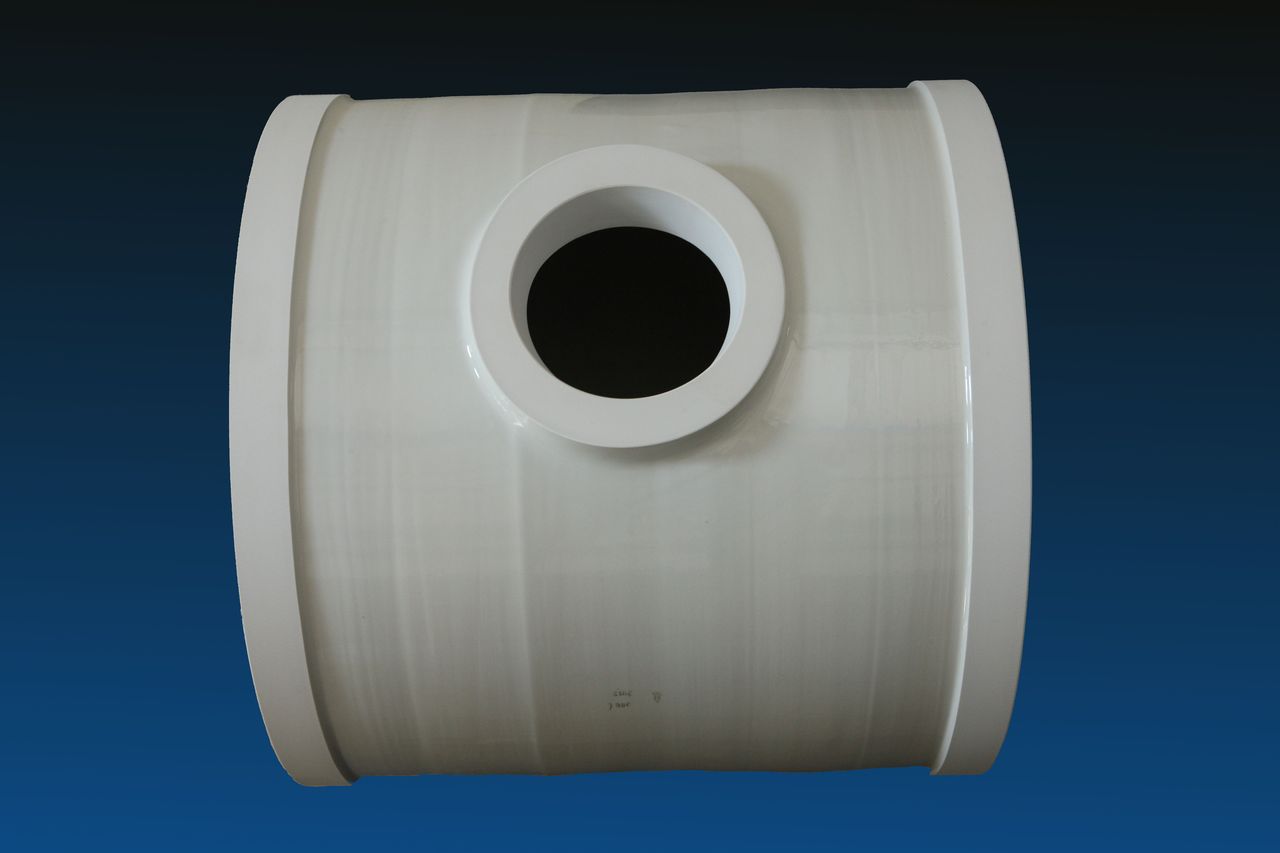

Tumbling mills

Ceramic tumbling mills can be used for grinding and mixing processes that contain aqueous and organic solutions as well as dry matters.

They are produced solidly out of one piece which prevents gaps and cracks. Another important advantage is that impurities from metallic ions or synthetic materials are impossible, which other coated mills cannot guarantee.

Our ceramic tumbling mills are applied for grinding and or mixing of minerals, colors and other materials in different areas like the chemical, pharmaceutical or electronic branch as well as in laboratories.

Often they are also used for preparation of ceramic mixtures, fluorescent paints, glazes and dental prosthesis.

We manufacture the ceramic tumbling mills out of hard porcelain C 110 in various sizes.

Possible volumes: 21/30/40/90/100/200/250/300 Liters.

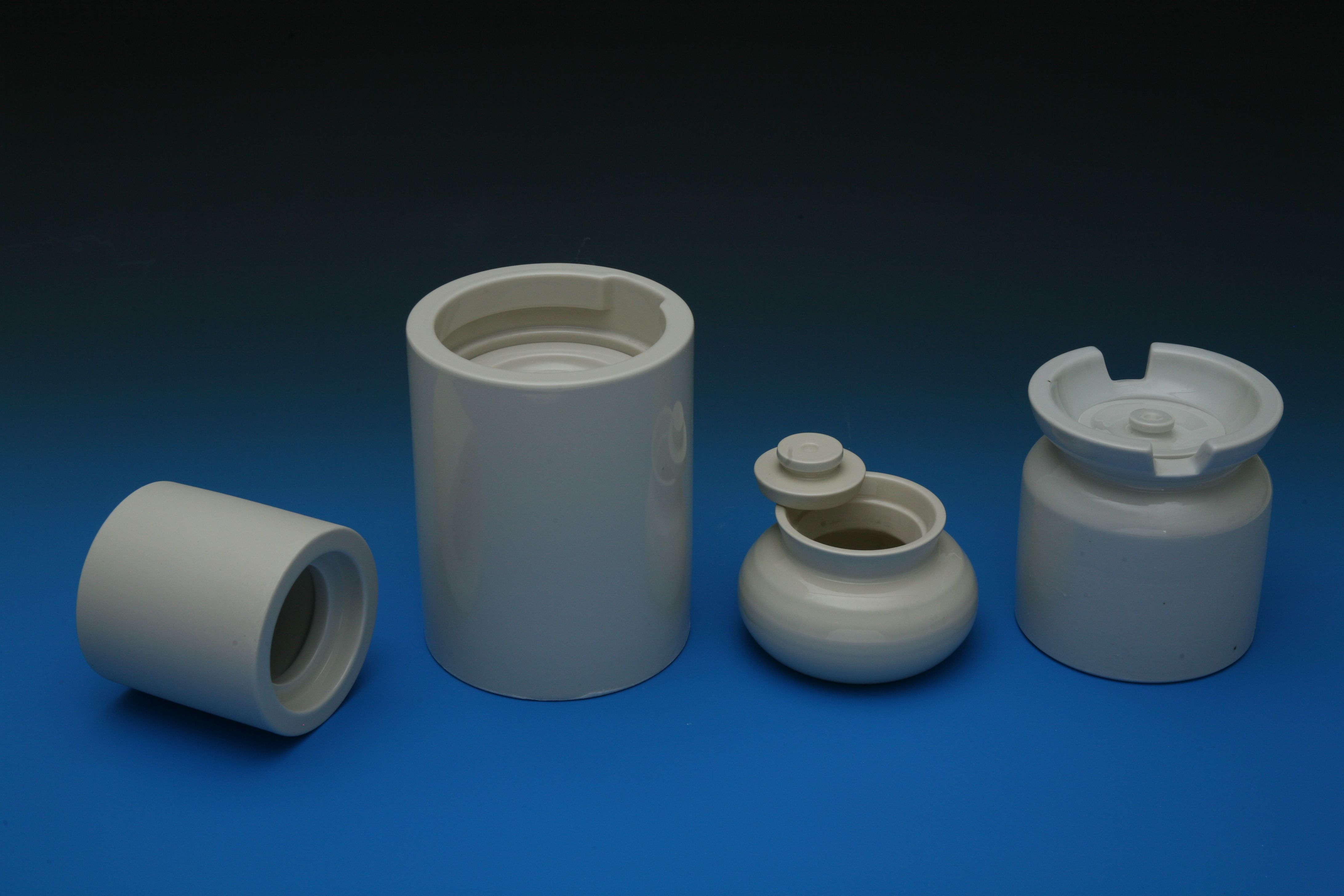

ball mills/grinding can

Ball mills made up of hard porcelain C110 are closing the gap between drum mills and bushings. It is possible to use them for labor mills or jar mills. We produce the ball mills in various sizes.

Possible volumes: 0,5/1/1,5/2/3/5 Liters.

Grinding balls

We produce ceramic grinding balls made up of alumina porcelain (C 130). They are used especially in the food and chemistry branch or the pharmaceutical branches, because metallic quarrels are not allowed there.

We offer them in various diameters from 20 mm up to 100 mm.

Both types can be applied as grinding bodies in all grinding beads.

Grinding balls made up of hard porcelain C 110 can be requested.